Room raised floor is a flooring system specially used in computer rooms, data centers and other places. Note the following when using the raised floor in the equipment room:

I. Personnel operation

Restricted movement

In the machine room, the walking route of the staff should be clearly specified, and the random walking in the raised floor area should be avoided as far as possible. Because frequent walking may cause uneven pressure on the floor, resulting in deformation or damage to the floor. Especially in areas where precision equipment is installed, the entry of irrelevant personnel should be strictly restricted.

For the personnel who need to enter the raised floor for maintenance and other operations, ensure that they are wearing appropriate overalls and work shoes to avoid sharp objects on the clothing (such as metal buttons, zippers, etc.) scratching the floor surface or the support structure below.

Correct operating posture and movement

When the staff need to carry equipment or tools on the raised floor, the correct posture should be adopted to avoid excessive impact of heavy objects on the floor. For example, when placing heavy server cabinets, it is necessary to lift lightly, and when using forklifts or pallet trucks, it is necessary to control speed and smoothness.

It is strictly prohibited to jump, run and other strenuous activities on the raised floor, which may cause the floor to loosen, shift, or even damage.

2. Equipment installation and maintenanceEquipment installation specifications

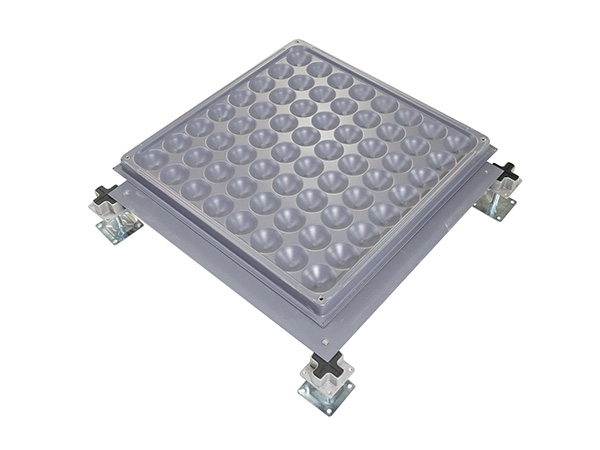

When installing the equipment, ensure that the weight of the equipment is evenly distributed on the floor. For heavier equipment, you should understand the carrying capacity of the raised floor in advance, and choose a reasonable placement according to the size and weight of the equipment. If the equipment is too heavy, additional support structures may need to be added under the floor.

The equipment should be installed in strict accordance with the manufacturer's installation guide. When fixing the device, pay attention to avoid excessive tightening of bolts and other connectors to prevent damage to the floor surface. At the same time, it is necessary to check whether the bottom of the equipment is smooth, if there is an uneven situation, measures should be taken to adjust, such as the use of gaskets.

Precautions for maintenance operations

Regular inspection and maintenance of the raised floor is very important. During the inspection process, pay attention to check whether the floor surface has scratches, cracks or deformation. If a slight scratch is found on the surface, it can be treated with an appropriate floor repair material; For more serious cracks or deformation, the floor plate may need to be replaced.

When you perform maintenance under the raised floor (for example, checking cables and ventilation pipes), take care to avoid collision or damage to the supporting structure and floor plates. When moving the floor plate, handle it gently to prevent damage to the plate edge. After the maintenance is complete, ensure that the floor plates are properly installed and securely secured.

Three, environmental

Temperature and Humidity control

The ambient temperature and humidity in the equipment room affect the performance and service life of the raised floor. Keep the temperature and humidity in the equipment room within an appropriate range. Generally, the temperature is controlled at 18-27 degrees Celsius, and the relative humidity is 40% to 60%. Excessive humidity may cause floor deformation and mold; Low humidity may cause static electricity problems.

The ambient temperature and humidity can be controlled by installing air conditioning systems and humidity regulating devices. At the same time, check the running status of these devices regularly to ensure that they can effectively maintain the environmental conditions of the equipment room.

Cleaning requirements

It is important to keep the surface of the raised floor clean. Clean the floor surface regularly to remove dust, paper scraps and other debris. For stains, you can use a mild cleaner and a soft rag to wipe, but avoid the cleaner seeping under the floor.

During the cleaning process, care should be taken to avoid water entering the floor below. If water enters the floor accidentally, clean it up and check whether there is standing water under the floor to prevent damage to cables and devices.

Four, cable managementCable laying specifications

When laying cables under an elevated floor, follow reasonable routing rules. Cables should be neatly arranged to avoid entanglement and confusion. You can use tools such as cable Bridges and cable troughs to arrange cables and ensure that cables have enough space and are not squeezed.

Pay attention to the weight and distribution of cables to avoid excessive concentration of cable weight in a certain area, which may cause excessive local pressure on the floor. For heavier cable bundles, additional support measures may need to be added.

Cable Inspection and maintenance

Periodically check the cable status, including whether the cable cover is damaged and the connector is loose. If any cable is faulty, repair or replace it in time. During the check, exercise caution to avoid affecting the stability of the raised floor when cables are moved.