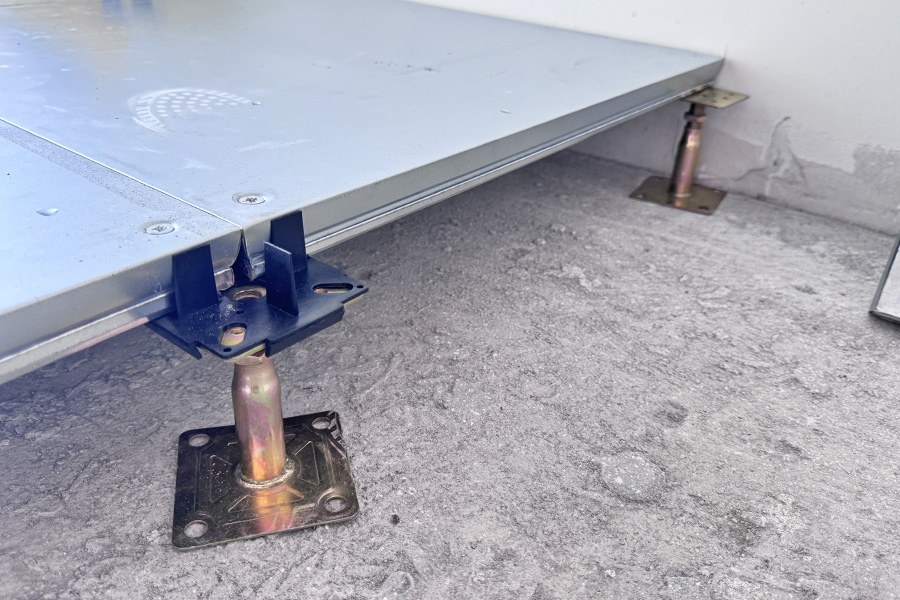

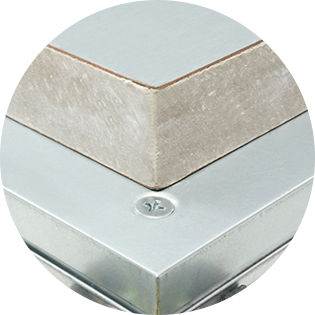

By utilizing the characteristics of calcium sulfate short fibers, the core material is made by dehydration crystallization. Then, high-quality galvanized steel plates are used to wrap the core material in a hexahedral shape. Due to the higt temperature of calcium sulfate reaching 1450 'c during the design and manufacturing of flooring, the upper and lowel layers of galvanized steel plates are seamlessly connected, which effectively blocks heat conduction and increase fire escape time! By utilizing the properties of calcium sulfate, the four corners of the floor can expose the core by 2-3mm, and can self regulate the indoor air dryness and humidity. Four cornered locking holes.

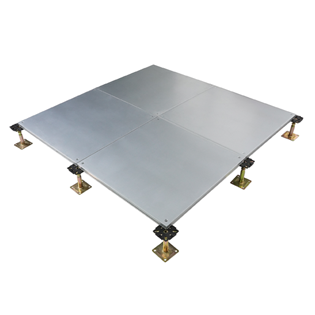

| Calcium sulfate six sided steel clad elevated floor | ||||||||

| model | specifications | concentrated load | Uniform Load | ultimate load | Fire resistance performance | Remarks | ||

| LB | N | KG | ||||||

| LP-LMBG600P | 600*600*26 | 800 | 3550 | 360 | 16000 | 10680 | A | |

| LP-LMBG600B | 600*600*30 | 1000 | 4450 | 450 | 23000 | 13350 | A | |

| LP-LMBG600Z | 600*600*30 | 1250 | 5560 | 560 | 33000 | 16680 | A | |

Hexagonal galvanized steel, flame retardant and high temperature resistant,non-deforming and non-fading

Made of high-quality steel base material.high density, hard quality. pressure-resistant,impact-resistant

high-quality cold-rolled steel cross reinforcement ribs make the floor rust-free and stronger bearing

finish Galvanized steel material fireproof,anti-slip